The power of Revit automation for structural detailing.

Problem

Planeamento e Projectos de Engenharia (PPE) is a company actively looking forward to improving their internal processes, saving time, and cutting off their production costs. Being an engineering company focused on structural design projects, one of the most time-consuming and repetitive tasks is structural framing reinforcement detailing workflow.

Challenges and Objectives

PPE’s main objective is to deliver the best structural engineering know-how and more detailed project information to their clients. To achieve that, they went through traditional workflows and identified some of the most time-consuming tasks.

With the evolution of technological resources, they concluded that those structural framing reinforcement detailing must be optimized. Reduction of production costs, efficiency and the time to deliver projects were the objectives that lead them to look for a bespoke solution.

Solution

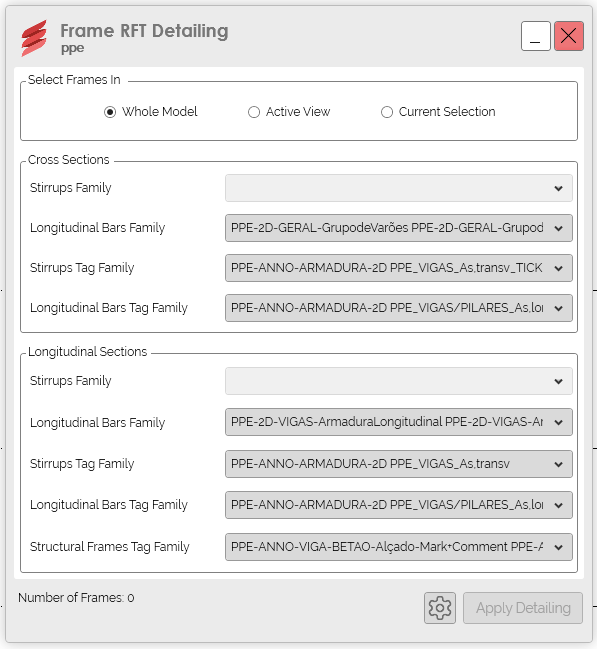

Develop a custom Revit add-in to automate section views creation and reinforcement detailing, including annotation/tagging and dimensioning.

Solution’s detailed workflow:

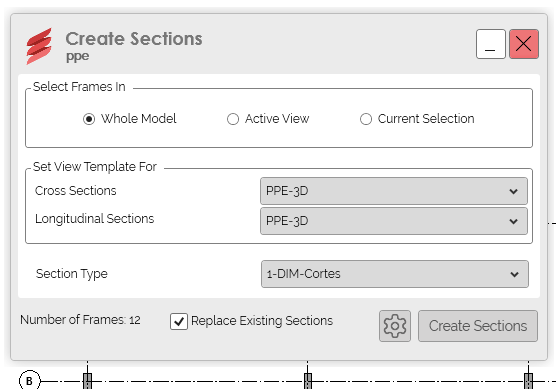

1 – Creation of several ‘Section Views’ as per their structural framing specifications

1.1. Selection of the ‘View Templates’ and ‘Section Types’

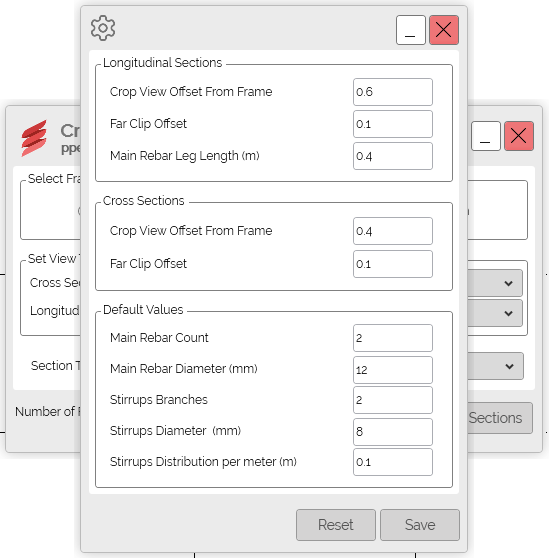

1.2. Definition of additional settings

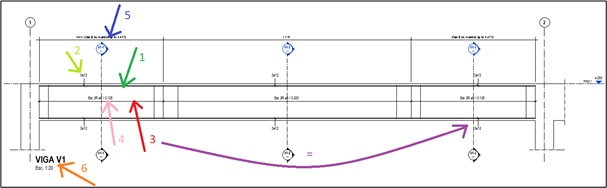

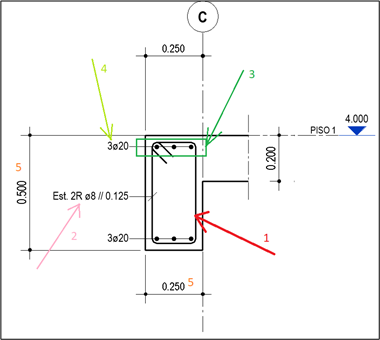

1.3. Generating the ‘Section Views’ (e.g., cross and longitudinal sections)

2. Selection of reinforcement detailing specifications to be applied on each beam type

Results

PPE reported that their drawing production workflow for structural beam detailing has been optimized by over 90%. In addition to the tremendous time savings, the detailing process is also less error-prone, which is also a crucial key performance indicator (KPI) for their business.

Due to automation, PPE can now deliver faster and efficiently, translating into higher revenue and client satisfaction, as well, a great return on investment (ROI).

More than that, DiRoots has excessed the initial PPE expectations and a being of a long-term automation partnership.

Filipe Ribeiro

Partner | Structural Engineer

Client Feedback

Why did you find our services to be the right choice for your business?

We know that DiRoots have skilled professionals in AEC software development since they produce some of the best add-ins for REVIT. We also knew that they make Custom Software solutions that fit the specific needs of each company. So, these 2 reasons together lead us to the choice of DiRoots for the development of our Custom Software.

How has DiRoots team helped ensure your success?

It was a straightforward process, and they understood very well what we were asking for.

Did DiRoots help you overcome the previous challenges?

The goal of this add-in is to simplify the process of the drawing workflow for Structural Beam detailing. With it, we can optimize the time for this specific task by about 90%.

Talk about the problems that you solved using the PPE Custom Revit Add-in

In addition to saving time, the detailing process is also more error-free, which is a very important improvement too.

What are some of your favorite features of the PPE Revit Add-in?

– It is simple to use;

– It’s fast;

– It fits our company standards.

What would you tell to someone who is not investing in automation to convince them that it is worth making the investment?

I would tell them that the AEC reality today is asking for this kind of optimization. All the BIM process can be implemented more quickly since it is here, and as we saw in the transition from hand drawing to CAD, there is no turning back.