The power of Revit automation for Modeling, Detailing, and Drawing Production.

Problem

Our client is a Southeast Asian main contractor looking forward to improving its internal processes, saving time, and reducing production costs. Being involved in different structural projects, this company was spending a large amount of the time and project’s budget with modeling, annotating, scheduling, and drawing production for the concrete rebar reinforcement. These were identified as the most time-consuming and repetitive tasks in their structural shop drawings workflow.

Challenges and Objectives

This company’s main objective is to deliver quality, detailed project information and the best structural engineering knowledge to their clients. To achieve that, they identified the following challenges and objectives:

– Standardize typical and custom rebar modeling that can be saved and reused across multiple projects.

– Automate the scheduling and drawing production.

– Create a less error-prone workflow, considering the high risk of human error when a lot of manual work is involved.

With the evolution of technological resources, they concluded that having a custom software solution to automate the reinforcement modeling/detailing is the right choice.

Solution

Develop a custom Revit add-in to:

– automate the longitudinal section views creation and reinforcement detailing (annotation/tagging).

– automate the scheduling and sheets creation (with schedules automatically placed).

– automate the 3D modeling (advanced 3D concrete rebar reinforcement modeling for concrete elements such as beams, columns, footings/pile caps, and slabs/floors).

Solution’s detailed workflow:

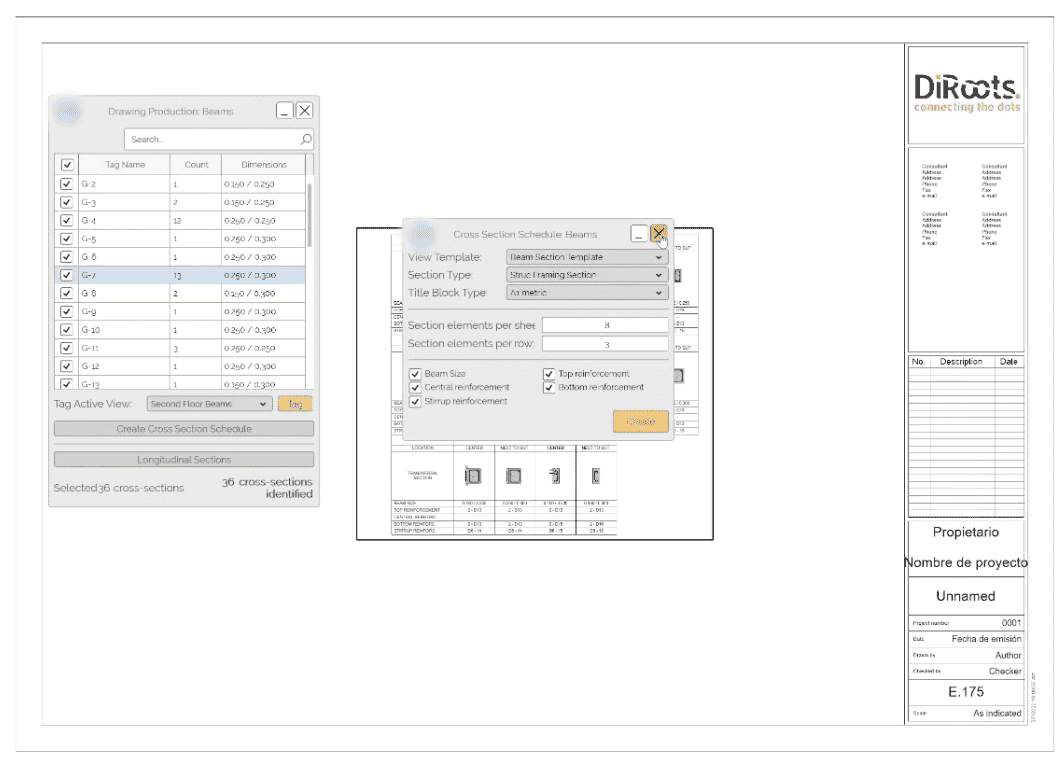

1 – Automated detailing, section creation, scheduling, and drawing production (beams, columns, footings/pile caps, and slabs/floors)

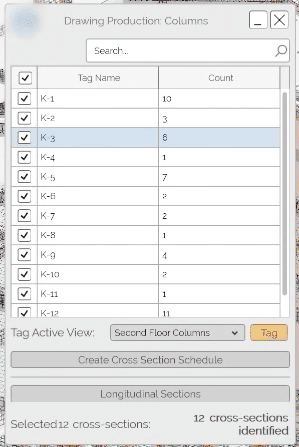

1.1. Smart identification and selection of common Rebar elements

1.2. Automatic annotation/tagging.

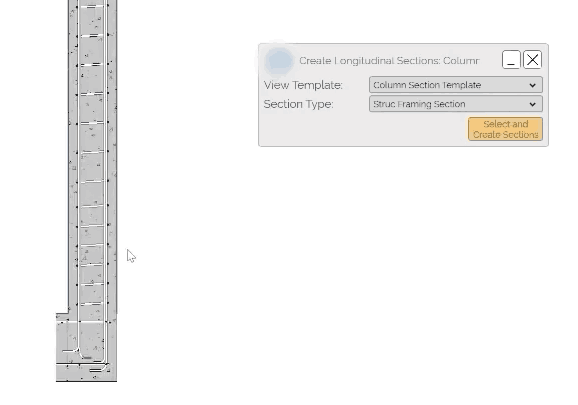

1.3. Generating the longitudinal structural framing section views based on a pre-defined view template.

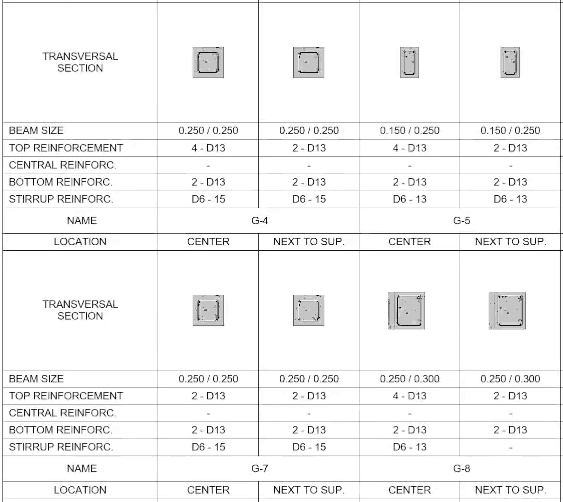

1.4. Auto Rebar Scheduling of all transversal sections per client requirements. Data such as name, location, dimensions, top reinforcement, central reinforcement, bottom reinforcement, and stirrup reinforcement is extracted from the current model to create custom schedules. After creating the schedules, the plugin automatically creates the necessary drawing sheets and places the schedules on the sheets.

2. Modeling Automation – beams, columns, footings/pile caps, and slabs/floors.

2.1 Advanced Configurator developed as per the client’s unique requirements.

2.1 Results of the Rebar 3D modeling automation.

As demonstrated in the video, this Revit plugin does the same for beams, columns, footings/pile caps, and slabs/floors.

Results

Through automation, DiRoots managed to increase its productivity, scale its production, and gain a significant competitive advantage in the market. With a custom Revit plugin, this company has seen over 90% time savings compared to the traditional concrete rebar reinforcement workflow.